The fascinating numismatic collectibles were created amid the upheaval in US coinage that occurred during the 1960s and 1970s.

More than 150 patterns and planchets that were created amid major changes in US coinage in the 1960s and 1970s ó all certified by Numismatic Guaranty Company™ (NGC®) ó are being offered in a Heritage Auctions sale. Bidding is already underway for the INCO and Gould Patterns Showcase Auction, which concludes on November 1, 2021.

Among the highlights is a (1977-78) Gould $1 graded NGC MS 64 RB (lot 46127) with impressive copper toning. In the 1970s, Gould Inc. struck tokens such as this one showing George Washington in order to demonstrate new compositions for planchets. At the time, the US Mint was considering how to shrink the Eisenhower Dollar, which many people found too inconvenient to carry around.

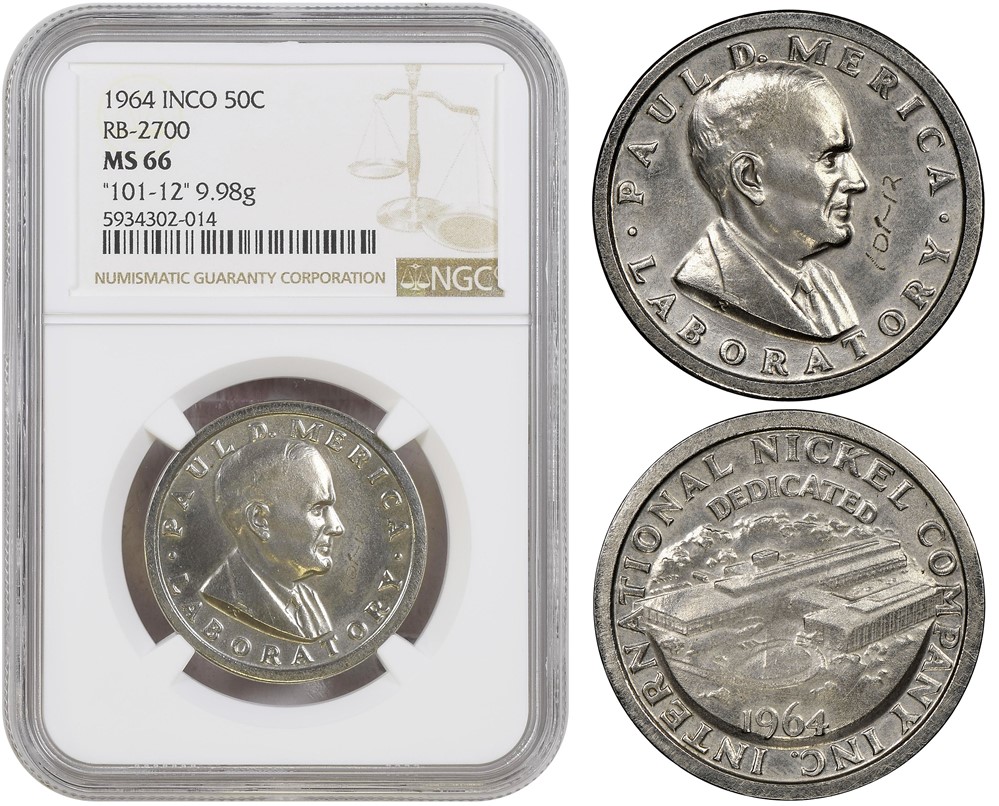

The sale also includes International Nickel Co. (INCO) patterns from a decade earlier, such as this 1964 INCO 50 Cents graded NGC MS 66 (lot 46029). It shows Paul D. Merica, the former president of INCO. The US Mint at the time was exploring options for planchets as the era of silver in circulating coinage was coming to a close.

Opportunities amid the farewell to silver

The Coinage Act of July 23, 1965 removed all silver from US dimes and quarter dollars and reduced the net silver content of the half dollar from 90% to 40%. These provisions became effective with the coins dated 1965, though none of the resulting pieces would be seen by the public until the fall. The new quarters debuted in November, the dimes in January of 1966 and the halves two months later.

In the meantime, production of the old .900 fine silver coinage occurred concurrently with the new "clad" coins, and all such pieces bore the date 1964 as late as the openings months of 1966. Along with the suspension of mintmarks for all coins dated 1965-67, regardless of where they were struck, it was a very confusing time for both the public and coin collectors.

The US Mint had known as early as 1964 that the removal of silver from circulating coins was inevitable, and it didnít wait for such a law to be passed before testing suitable replacement alloys. The new coins would have to look somewhat like silver to gain public acceptance, and they would also have to function as well as the old issues in parking meters, vending machines and elsewhere. Exactly what composition would prove to be suitable required extensive testing, and to perform these tests the Mint drew upon the expertise of American industry.

INCO test pieces are collectible today

The companies that provided blanks and tokens of proposed alloys did so at their own expense, believing that it was a worthwhile investment in possibly securing a contract to supply the composition ultimately selected by the Mint and Congress. Though DuPont struck trial medals utilizing its "Detaclad" laminate composition that were found satisfactory in tests with pay telephones and vending machines, it was International Nickel Company that made the most extensive tests and provided a broad range of test pieces that today are highly collectible.

During 1964-65, INCO contracted with Medallic Art Company to strike sample pieces from its various alloys. The resulting token-like "coins" were provided to the US Mint for its own studies. Also furnished were unstruck blanks that could be struck by the Mint if desired. These were made in sizes corresponding to dimes, quarters and halves.

The extensive series of INCO trial pieces are known with a variety of designs that simulate the sort of elements that would be used on actual coins. A portrait of Paul D. Merica, former president of the company, was paired with a view of the research facility named for him as the obverse and reverse designs for tokens used extensively for testing in 1964. These "coins" are actually dated with that year.

Other test pieces bear text only, while some have just raised mounds on either side to simulate a typical height of relief. Most commonly used are assorted blends of copper and nickel, but other pieces were made that include silicon, chromium, zinc, aluminum, vanadium ó the list of non-precious metals tested is a long one.

Another major coin change

In 1976, the US Mint commissioned the Research Triangle Institute to perform a study of Americaís existing coinage with a view toward its future needs. Among the recommendations found within RTIís report were the elimination of the half dollar denomination and the replacement of the existing Eisenhower Dollar with a dollar coin of smaller size. In fact, the US Mint had been drawn to this conclusion already the previous year, since the National Automatic Merchandising Association reported that the poor circulation of Ike Dollars was precluding its members from adopting a dollar coin slot for their machines.

As in 1965, the question arose of what composition to use for the proposed "mini dollar." The Mint wanted to retain the familiar copper-nickel-clad composition used already for dimes through dollars, but this decision was arrived at after the testing of several alternative alloys, some of which were the product of sintering and powdered metal compression. Since the Mintís own facilities could not perform these processes, it contracted with Gould Inc. to provide sample planchets of the proposed mini dollar size that the Mint struck with its familiar test dies featuring Martha Washington and Mount Vernon.

These samples proved unsatisfactory to the Mint for a variety of technical reasons, and that was when the decision was made to go with proven clad composition. Gould, however, was not inclined to give up so easily. From 1976 to 1978, it produced a series of test tokens featuring a portrait of George Washington recycled from the products of Washington Mint Inc. This was paired with three slightly different versions of the Great Seal of the United States for the reverse.

The test pieces were produced in a variety of compositions, and among the metals utilized were aluminum, copper, iron, nickel and titanium. The US Mint was not persuaded to change its plans, however, but the Gould specimens survive in limited numbers as fascinating reminders of what might have been.

The INCO and Gould tokens and medals were researched thoroughly by Roger W. Burdette, who published his findings in a book titled Private Pattern and Related Pieces: International Nickel & Gould Incorporated.