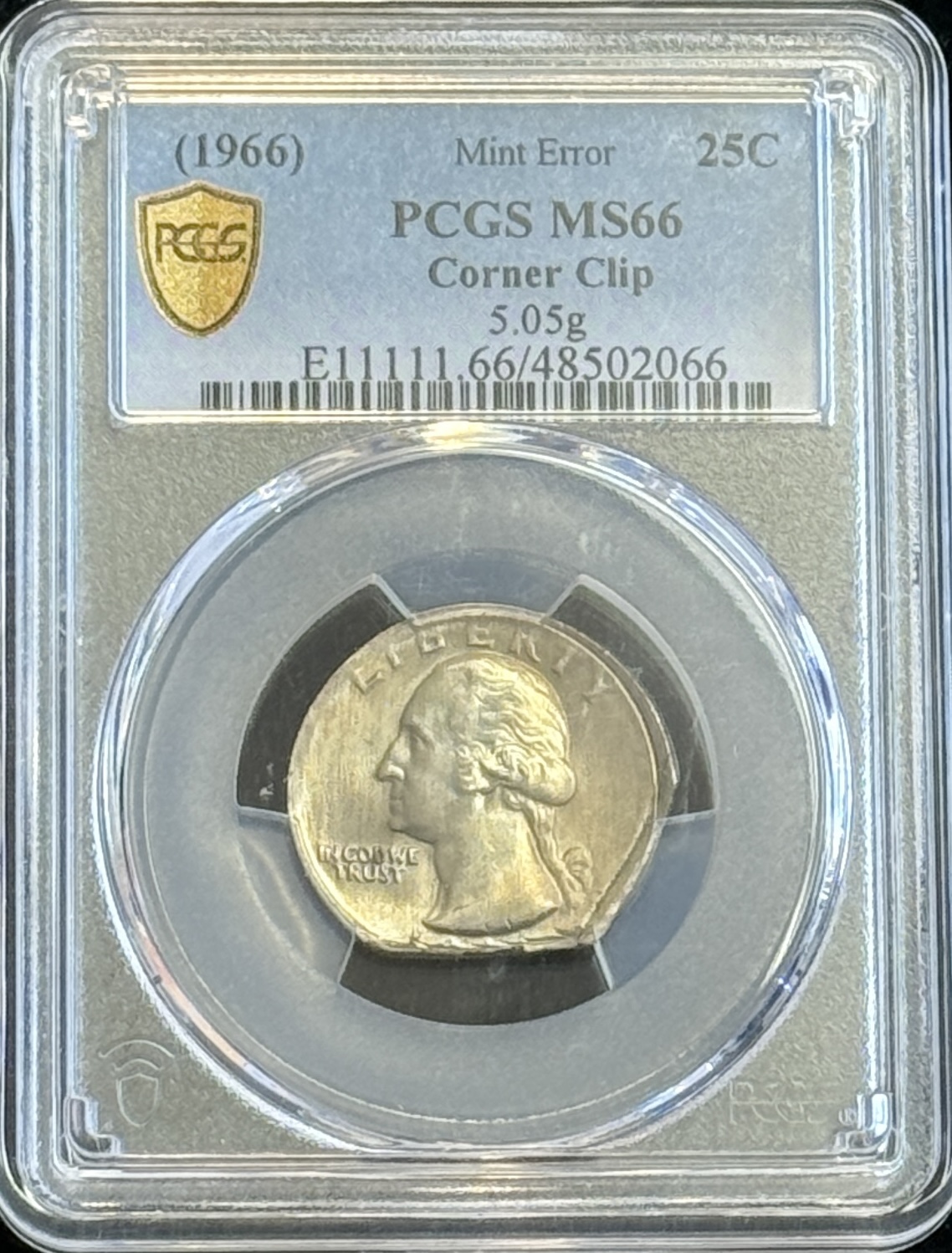

I absolutely love major mint errors. I wouldn't be here if I didn't. But I especially love examples that are both extremely rare error types and also visually interesting. I have a coin to showcase this time around which covers all those bases and more. Welcome to the world of corner clips. This is a fantastic example of the type.

I absolutely love major mint errors. I wouldn't be here if I didn't. But I especially love examples that are both extremely rare error types and also visually interesting. I have a coin to showcase this time around which covers all those bases and more. Welcome to the world of corner clips. This is a fantastic example of the type.

Corner clips are extremely rare, and examples this nice are absolutely impossible to come by. This was a recent acquisition, and I'm happy to share it with you because it explains a little-known part of the minting process. Whenever we learn about the minting process, we learn more about the coins we can potentially buy and we can make better and more informed buying decisions. This is essential especially when buying major and more expensive error coins, which is something I always support doing! We certainly don't want to make mistakes, and mistakes will happen far less often the more educated we are.

Corner clips are extremely rare, and examples this nice are absolutely impossible to come by. This was a recent acquisition, and I'm happy to share it with you because it explains a little-known part of the minting process. Whenever we learn about the minting process, we learn more about the coins we can potentially buy and we can make better and more informed buying decisions. This is essential especially when buying major and more expensive error coins, which is something I always support doing! We certainly don't want to make mistakes, and mistakes will happen far less often the more educated we are.

So, let's dive into this error type and take a look at what's happening here. At first glance, this looks like something that somebody could easily make in a garage with a pair of tin snips and a quarter, but I will explain instead how this type of error actually happened.

So, let's dive into this error type and take a look at what's happening here. At first glance, this looks like something that somebody could easily make in a garage with a pair of tin snips and a quarter, but I will explain instead how this type of error actually happened.

We all know about clipped planchets. When a planchet strip is being fed into the planchet cutting machinery at the mint, if the strip doesn't advance fully through the machine, or if a previously cut blank hops back onto uncut strip and is itself then recut, but only partially by the planchet cutters, you get a clipped planchet. These are common error types, with some more interesting than others, but generally they are common and easily found, depending on the denomination and series. A clipped wheat cent might be common, but a clipped gold coin would be an interesting coin indeed!

We all know about clipped planchets. When a planchet strip is being fed into the planchet cutting machinery at the mint, if the strip doesn't advance fully through the machine, or if a previously cut blank hops back onto uncut strip and is itself then recut, but only partially by the planchet cutters, you get a clipped planchet. These are common error types, with some more interesting than others, but generally they are common and easily found, depending on the denomination and series. A clipped wheat cent might be common, but a clipped gold coin would be an interesting coin indeed!

There are, of course, straight and ragged clips too which result when a planchet is cut from around the straight end of a planchet strip or a ragged end of the planchet strip. A far less common - indeed exceedingly rare and little-known error type is the corner clip.

There are, of course, straight and ragged clips too which result when a planchet is cut from around the straight end of a planchet strip or a ragged end of the planchet strip. A far less common - indeed exceedingly rare and little-known error type is the corner clip.

In order to feed the planchet strip into the planchet cutter, mint employees need to make that planchet strip have a new shape that feeds more easily into the mouth of the planchet cutting machinery. The planchet strip is at a 90 degree angle at its leading and trailing edge. Because the planchet cutting machinery is of the same width as the planchet strip itself, it would be extremely difficult for mint employees to feed the 90-degree angles into the machine as they would get jammed up at the corners.

In order to feed the planchet strip into the planchet cutter, mint employees need to make that planchet strip have a new shape that feeds more easily into the mouth of the planchet cutting machinery. The planchet strip is at a 90 degree angle at its leading and trailing edge. Because the planchet cutting machinery is of the same width as the planchet strip itself, it would be extremely difficult for mint employees to feed the 90-degree angles into the machine as they would get jammed up at the corners.

So, to make this job easier, they make a tongue of sorts by cutting a 120-degree angle on either side of the leading and trailing edge of the planchet strip. This makes it absolutely possible and much easier for that planchet strip to be fed into the machine, much like an old typewriter, where you fed the paper in and then rolled the typewriter a little bit in order to feed the paper through before you started typing.

So, to make this job easier, they make a tongue of sorts by cutting a 120-degree angle on either side of the leading and trailing edge of the planchet strip. This makes it absolutely possible and much easier for that planchet strip to be fed into the machine, much like an old typewriter, where you fed the paper in and then rolled the typewriter a little bit in order to feed the paper through before you started typing.

It is the same at the mint with the planchet strip. The strip is fed into the machine more with ease due to those 120-degree angles, allowing the strip to get into the machine more readily. Then planchets are cut from that strip. If the machine isn't turned off by the time the planchet strip is fed all the way through, the trailing edge - which also has the angles cut - will most definitely be have the potential of having planchets cut from it along those two corners (those that have those angles cut into it).

It is the same at the mint with the planchet strip. The strip is fed into the machine more with ease due to those 120-degree angles, allowing the strip to get into the machine more readily. Then planchets are cut from that strip. If the machine isn't turned off by the time the planchet strip is fed all the way through, the trailing edge - which also has the angles cut - will most definitely be have the potential of having planchets cut from it along those two corners (those that have those angles cut into it).

That is what has happened here. As evidence that we are all potentially learning something new all the time, even in the case of myself after 45 years of experience in error coins, I will share something I learned just last week about this very coin. It was during a conversation with a senior numismatist to myself just last week that he informed me about the fact that in 1966 when this coin was struck, it was indeed the trailing - not leading - edge of the planchet strip which created this corner clip. I tell you this so that you stay inspired, and know that its ok not to know. We are all learning together. Remember, more information leads to more confident buying decisions.

That is what has happened here. As evidence that we are all potentially learning something new all the time, even in the case of myself after 45 years of experience in error coins, I will share something I learned just last week about this very coin. It was during a conversation with a senior numismatist to myself just last week that he informed me about the fact that in 1966 when this coin was struck, it was indeed the trailing - not leading - edge of the planchet strip which created this corner clip. I tell you this so that you stay inspired, and know that its ok not to know. We are all learning together. Remember, more information leads to more confident buying decisions.

As you can imagine, examples of corner clips are few and far between, because they have to happen, meaning be cut in the first place, which is rare. Then they would have to make it through the minting process which is rarer still. Then they would have to make it out of the mint which is even more rare. And to use the word "rare" isn't even fair, because prime examples of corner clips like this one are exceedingly rare.

As you can imagine, examples of corner clips are few and far between, because they have to happen, meaning be cut in the first place, which is rare. Then they would have to make it through the minting process which is rarer still. Then they would have to make it out of the mint which is even more rare. And to use the word "rare" isn't even fair, because prime examples of corner clips like this one are exceedingly rare.

One thing I like about this coin is that its appealing to me. Corner clips are almost as rare as the people who know what they are, which I mention because eye appeal is everything. Look at dozens, even hundreds, of major mint errors. I would advise to buy the coin that appeals to you. Sometimes this takes a bit of a financial stretch (as was the case with this corner clip) but the stretch yields incredible satisfaction if the coin you are desiring is one that you understand, know about, and appreciate.

One thing I like about this coin is that its appealing to me. Corner clips are almost as rare as the people who know what they are, which I mention because eye appeal is everything. Look at dozens, even hundreds, of major mint errors. I would advise to buy the coin that appeals to you. Sometimes this takes a bit of a financial stretch (as was the case with this corner clip) but the stretch yields incredible satisfaction if the coin you are desiring is one that you understand, know about, and appreciate.

I hope you have gained an understanding, knowledge, and appreciation about corner clips from what I have shared here.

I hope you have gained an understanding, knowledge, and appreciation about corner clips from what I have shared here.

This is one of only a few examples I've seen in my years collecting, and is certainly the finest known, as far as I can tell. It is certainly one of the most visually striking known examples, which was why I was happy to add it to my collection.

This is one of only a few examples I've seen in my years collecting, and is certainly the finest known, as far as I can tell. It is certainly one of the most visually striking known examples, which was why I was happy to add it to my collection.

As always, if you have questions about error coins, please let me know at minterrors@gmail.com. I would always be happy as well to answer questions sent in to Mike Byers directly himself, as we are in touch, and he's happy to forward questions to me. Thanks so much for reading and I look forward to our next article and hearing about your next purchase of a valuable and rare major error coin.

As always, if you have questions about error coins, please let me know at minterrors@gmail.com. I would always be happy as well to answer questions sent in to Mike Byers directly himself, as we are in touch, and he's happy to forward questions to me. Thanks so much for reading and I look forward to our next article and hearing about your next purchase of a valuable and rare major error coin.